In today’s fast-paced technology landscape, the speed of innovation directly determines market competitiveness. Hardware startups, IoT developers, and established tech companies all face the same pressure — to validate concepts, iterate designs, and bring products to market faster than ever. This is where quick turn PCB prototyping becomes a key enabler of modern hardware development.

Innovation Speed Requirements

In the hardware industry, every week counts. Delays in prototype validation or manufacturing can ripple through an entire product cycle, pushing back launch schedules and increasing development costs. Rapid iteration is the foundation of modern innovation, especially in sectors like wearables, robotics, automotive electronics, and medical devices. A streamlined, quick-turn prototype assembly process enables engineers to move from schematic to physical board testing within days rather than weeks.

What Quick-Turn Prototyping Means

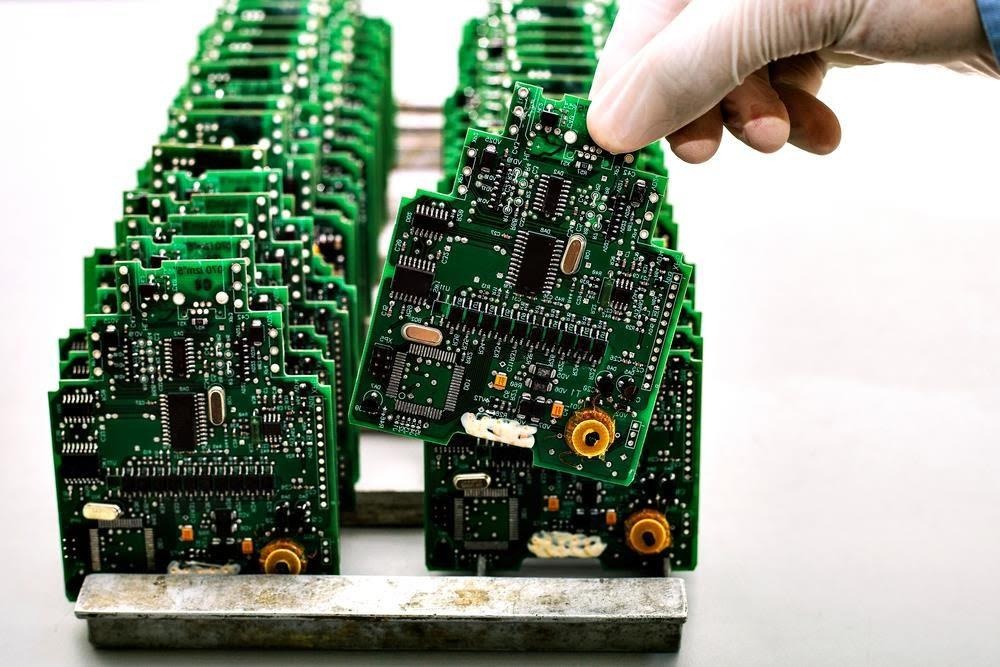

Quick turn PCB prototyping means producing circuit boards in 24–72 hours so engineers can test and refine designs quickly. This agile approach accelerates the design-build-test loop, enabling faster detection of flaws and a shorter path to production.

Importance of Design Validation

The prototyping phase is where most design flaws are discovered. Early detection saves time and money by preventing costly rework later in production. With fast quick turn PCB prototyping, teams can rapidly test multiple design versions in parallel, validate electrical performance, and ensure mechanical compatibility. This speed empowers hardware engineers to make informed decisions and move confidently into EVT (Engineering Validation Test) and DVT (Design Validation Test) phases.

Risk Reduction Before Scaling

Building hundreds or thousands of faulty boards due to an overlooked design issue can be catastrophic. Quick-turn prototyping minimizes this risk by allowing multiple iterations before scaling to mass production. The ability to verify component footprints, signal integrity, and manufacturability helps reduce downstream failure rates. Essentially, quick turn PCB prototyping for early-stage hardware innovation acts as a safety net—detecting issues early while supporting agile product refinement.

Industry Use Cases

From consumer electronics to aerospace, quick-turn prototyping is indispensable.

- IoT devices: Rapid hardware iterations for sensor integration and wireless modules.

- Medical devices: Fast testing cycles for safety-critical designs.

- Automotive electronics: Validation of power management and ECU circuits.

- Robotics and AI systems: Continuous hardware-software co-development and testing.

These industries rely on speed and precision, and a dependable, quick-turn PCB partner enables both.

FastTurn Prototyping Advantages

FastTurn PCB stands out for its proven ability to deliver high-quality, quick-turn prototypes with minimal lead times. With advanced in-house fabrication, automated assembly, and strict quality control, FastTurn supports engineers from initial design files through assembled prototypes. Whether you need single-layer boards for testing or complex multilayer assemblies, FastTurn provides rapid turnaround without compromising reliability.

Their simple ordering, 24/7 support, and DFM checks guarantee every prototype meets exact specifications—helping teams accelerate innovation and reduce time-to-market.

Conclusion

In an era defined by rapid innovation cycles, quick turn PCB prototyping is no longer optional—it’s essential. By shortening development timelines, reducing design risks, and enabling fast feedback, it empowers hardware teams to innovate with confidence. Partnering with a trusted manufacturer like FastTurn PCB ensures that your next great product moves from idea to prototype to market faster than ever.